pcb factory production, quality, technology three departments, which is more important

It is generally believed that there are push and pull things between various departments on the site of pcb factory , which not only affects the output and quality, but also affects the harmonious working relationship between departments. The root cause of the study is mainly due to the deviation of the understanding of the functions of various departments on the site. Of course, it does not rule out that some people obviously do not understand and pretend to understand. They are serious in mountainism and departmentalism and are good at tai chi. Now briefly explain the functional relationship of the three departments of production site, quality and technology for your reference.

pcb factory site production, quality, technology three departments is equal to ensure the national legislation, judicial, administrative separation of powers, each position, mutual checks and balances and supervision, on-site production efficient and orderly.

The Ministry of Technology, like the legislature of the country, formulates relevant regulations on the pcb factory site, namely, the production engineering flow chart and operation guidelines, inspection standards, methods, etc. of the pcb factory. Analyze and solve more than 6 problems of 5M1E on site. In principle, the working basis (I. e. input) of on-site production and quality personnel is provided (output) by the technical department, that is, only applicable to the technical department in Daegu.

The Quality Department should be the same as the judicial organs of the country, that is, the public security law (public security, procuratorate, court). The Quality Department should fully perform the functions of public security detection, investigation, evidence collection, the supervision and supervision functions of the procuratorial organs, and the judgment and tracking execution functions of the court. That is to say, according to the law to detect, supervise, judge, deal with all kinds of illegal discipline.

circuit board factory, circuit board factory tell you that the quality department should supervise the three major compliance on site, namely system compliance, process compliance and product compliance. Timely discover the inconsistencies of systems, processes and products (above), detect and analyze the causes of abnormalities, and urge relevant persons in charge to formulate corrective and preventive measures, and implement and confirm the effect until the closure is effectively improved.

The production department, like the administrative organ of the country, the people's government, is responsible for the daily implementation and management of laws and regulations (I. e. the rules of the factory and the production process documents). Production workers are like civilians and cannot demand too much from the common people. The Technical Department shall minimize reliance on the requirements and experience of the operator. The production department carries out administrative management, and its function is to strictly abide by discipline and perform work in strict accordance with the laws and regulations (engineering flow chart and operation guide) formulated by the technical department.

Operators standardize their work in accordance with the work policy of the Technology Department to ensure "compliance with the work process and process", but the output and quality are still not good. Whose responsibility is this? The answer is "Technology Department". The function of the technical department is to conduct research on processes, processes, methods, work clothes, etc. Therefore, it is necessary to continuously review the suitability, suitability and effectiveness of the production process and engineering, solve more than 6 sets of 5M1E on site, and continuously improve output and quality.

Good craftsmanship, craftsmanship is convenient for workers to produce and work, and it is easy to achieve work output and quality. Otherwise, find a way to continue to improve the process until the operator wants to be wrong. That is a difficult or impossible thing. There is a special name for this: error prevention. This is the direction and ultimate goal of the Department of Biotechnology. Site management also needs to improve management, clear function, unified understanding. On-site departments such as "barrel principle". The amount of the barrel is not determined by the size and height of the barrel, but depends on the height of the barrel "board" and the "close connection" between the boards. Therefore, the output and quality require the unified functional understanding and close cooperation of all departments on site.

pcb factory, circuit board factory, circuit board factory

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

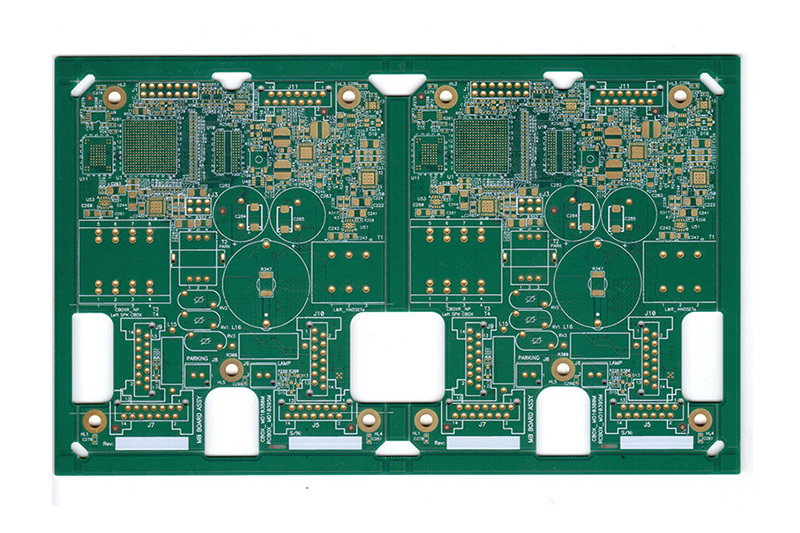

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.