How to choose a reliable circuit board pcb factory

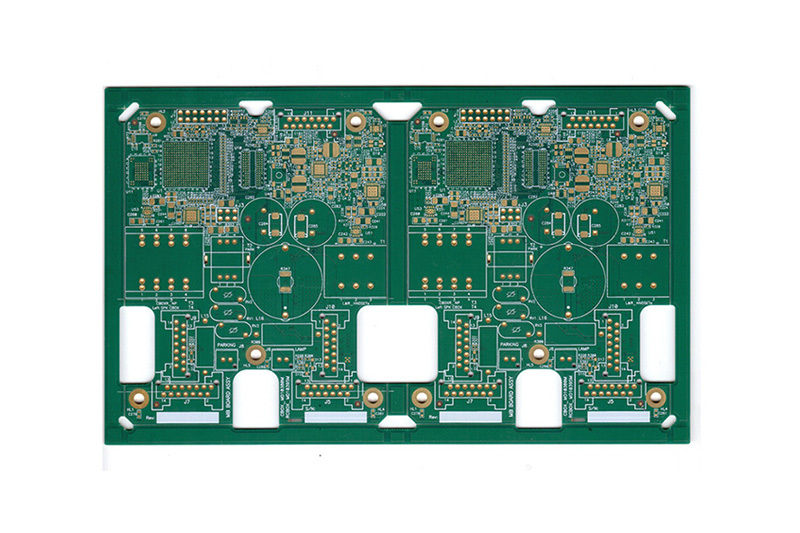

How to choose a reliable pcb factory , speaking of pcb factory, this is the simple English word. The industry will not be unfamiliar. PCB is what we call a circuit board everyday. With the development of electronic information age, more and more electronic products enter our life. Almost all the electronic products we use use circuit boards, which play an important role. Now many PCB factories also have great demand for circuit boards, and they are eager for it. The following describes the factors to consider when choosing a PCB factory.

to clear their own use, from their own use requirements to find the corresponding pcb factory. At present, there are many kinds of board factories on the market, including a large number of military boards, annual boards, small and medium-sized, sample boards, and only simple boards. There is no best, only the most suitable. If you find a matching track board manufacturer, you can first select samples for testing, and the predecessor track board sample factory can specifically calibrate the track board.

Secondly, choose regular professional circuit board enterprises must look at their production capacity. Review the strength of a circuit board factory, and look at several aspects

to see if he can independently complete the later electronic testing and milling processes from material opening to surface treatment. The most important are mainly optical imaging, etching, masking, surface treatment and drilling. Coupled with the process capacity, domestic small factories generally do 2 layers and 4 layers, and high-point 8-layer pcb. Powerful manufacturers can do standard 12-layer or even 26-layer circuit boards. The number of layers refers to the number of layers that the pcb can be wired. The pcb board is compressed into multiple single layers through the PP chip connection. There is no difficult technology in terms of interference between pcb lines, compression quality, and mechanical accuracy. There are also parameters provided by the supplier, such as processing capacity, line width distance, copper thickness, sealing layer thickness, etc. It is also important for circuit board factories to conduct strict quality checks on their products. The board factory can only enter the market after the appearance of each product is complete and the performance is perfect. The higher the requirements of the regular factory for quality inspection, the more professional the inspection process.

Then, for after-sales service, it is also important to choose a regular professional circuit board company. In other words, after the PCB demand company or company purchases the product, the factory may have no problem, but when it is used specifically, due to some reasons, the PCB board may have problems. If there is a problem with the product, the predecessor circuit sample factory will provide a series of after-sales services. To ensure the normal use of the product.

Finally, regarding the price, due to the different sizes and production capacity ranges of regular and professional pcb factories, their quotations are also different. If it is a regular professional circuit board manufacturer after comparative investigation, the factory has its own reasonable price system. Don't worry about prices. By choosing an acceptable and reasonable offer to cooperate with circuit board enterprises, do not choose informal majors on the grounds of coveting cheap. Follow-up questions may be so many. These are the factors that need to be considered when choosing a PCB factory. For more details, please consult us. Shenzhen circuit board factory selection also need to pay attention to, want to know more HDI circuit board, thick copper circuit board content, you can pay attention to us.

thick copper circuit board, pcb factory, shenzhen circuit board factory, HDI circuit board

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.