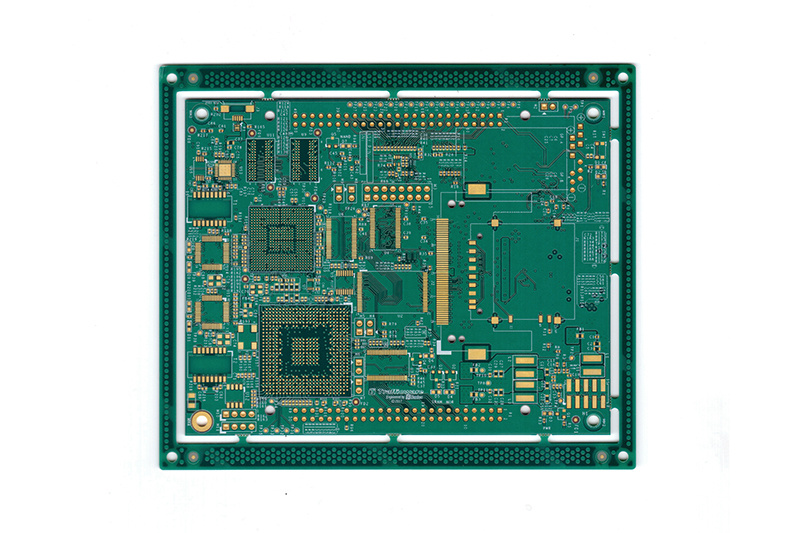

Multi-layer circuit board factory: reasons and solutions for layered blistering of multi-layer circuit boards

Multi-layer Circuit Board Factory In the graphic plating process, because the circuit pattern is prone to side etching during the etching process, the tin-lead alloy plating part is suspended and a suspension layer is generated, which is easy to fall off, resulting in a short circuit due to bridging between wires. Multi-layer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. What is the reason for the layered foaming quality problem of multi-layer circuit board?

Cause:

( 1 ) Improper pressing causes air, moisture and pollutants to be hidden in . Solution: Multi-layer Circuit Board Factory needs to bake and keep dry before laminating and pressing the inner layer of ; Strictly control the process procedures before and after pressing to ensure that the process environment and process parameters meet the technical requirements.

( 2 ) During the pressing process, due to insufficient heat, too short cycle, poor quality of prepreg, and incorrect press function, the curing degree has a problem . Solution: Check the Tg of the pressed multilayer board, or check the temperature record of the pressing process. The pressed semi-finished product, multilayer circuit board factory , is re-baked at 140 ℃ for 2-6 hours to continue curing treatment.

( 3 ) The inner line is poorly blackened or the surface is contaminated when blackened . Solution: Multilayer Circuit Board Factory strictly controls the process parameters of the oxidation tank and cleaning tank of the blackening production line and strengthens the inspection of the appearance quality of the board surface , Try double-sided copper foil .

( 4 ) The inner laminate or prepreg is contaminated . Solution: Clean management should be strengthened in the operation area and storage area ; Reduce the frequency of unarmed handling and continuous plate taking ; All kinds of bulk materials in stacking operation shall be covered to prevent pollution ; When the tool pin must be lubricated and unpinned, it shall be separated from the stacking operation area and cannot be carried out in the stacking operation area.

( ) Insufficient glue flow . Solution: Multi-layer Circuit Board Factory Appropriately Increase Pressing Pressure Strength ; Appropriately slow down the heating rate and increase the glue flow time, or add more kraft paper to ease the heating curve ; Replace prepreg with higher glue flow or longer gel time; Check whether the surface of the steel plate is flat and free of defects ; Check whether the length of the positioning pin is too long, causing the heating plate to be not tightly attached and causing insufficient heat transfer ;

Check whether the vacuum system of the vacuum multi-layer press is good.

( 6 ) Excessive glue flow-the glue content of the prepreg is almost all outside the extrusion board. solution: multilayer circuit board factory properly adjust or reduce the pressure ; The inner laminate before 111 pressing needs to be baked and dehumidified, because moisture will increase and accelerate the glue flow ; switch to semi-cured sheets with lower glue flow or shorter gel time.

( 7 ) Under the requirement of no function, the inner laminate shall minimize the occurrence of large copper surface (because the bonding force of resin to copper surface is far lower than that of resin to resin) . solution: multilayer circuit board factory try to etch away useless copper surface.

multilayer circuit board factory, multilayer circuit board, multilayer circuit board, blind buried via circuit board, PCB circuit board factory

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.