Shenzhen PCB Factory: Causes of Circuit Board Line Bending

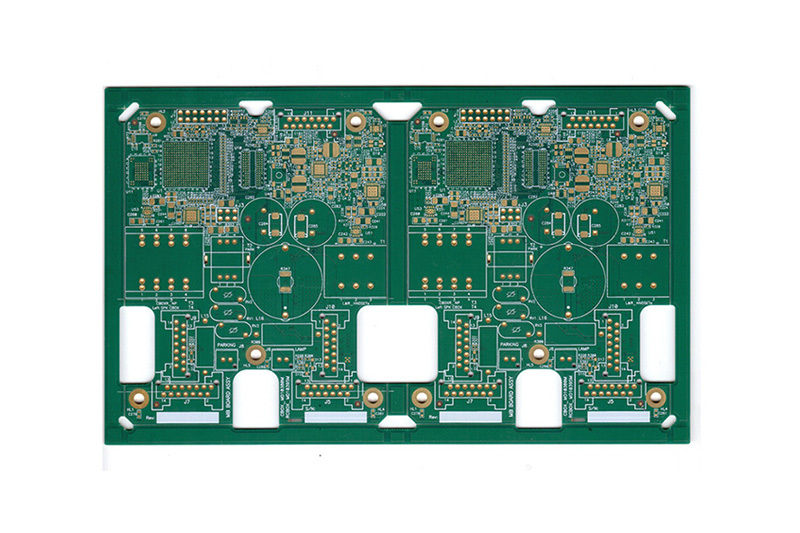

Shenzhen Circuit Board Factory, Multi-layer Circuit Board Factory tells you that with the rapid development of modern technology, various electronic products are becoming more and more indispensable in life. Some friends like to disassemble some old electronic products, and they will find that the circuit boards in electronic products are more complicated. Why is the circuit inside the circuit board a winding? We have the shortest straight line between two points. Can't the circuit board be designed in a straight line?

If the circuit in the circuit board is designed in a straight line, the area of the circuit board will increase several times. In today's era of pursuing exquisite and compact, the area of the circuit board is naturally as small as possible, otherwise it will directly affect the area of electronic products. It is estimated that people's requirements for electronic products are as follows: except for the larger screen, the smaller the better, and the thinner the better.

Even if we don't care about the size of the circuit board, designing the circuit in the circuit board in a straight line will cause other problems. On the circuit board, the circuit must rotate. If we design the circuit on the circuit board in a straight line, the angle of this turn will reach 90 degrees. Because the circuit is prone to large reflections when turning at 90 degrees, such circuit boards are easily broken during the production process. This will not only waste materials, but also prone to quality problems even if the circuit board is successfully manufactured.

Multi-layer circuit board factory, circuit board factory In order to ensure the stability of the signal, the circuit on the circuit board is designed to be bent. The design of the circuit board is a technical activity, and only the corresponding design can ensure the stability of the signal. Only when the signal is not disturbed, the chip on the circuit board can work normally. Each winding circuit on the

board represents a different signal. If the circuit on the circuit board is designed in a straight line, it is easy to cause mutual interference between signals, making our electronic equipment unable to work properly. If our mobile phone signal is disturbed, it is likely that there is a problem with the circuit board, and such a mobile phone can almost be declared scrapped.

Multi-layer circuit board factory, circuit board factory = tell you that the circuit board is composed of devices, capacitors, diodes, etc. These lines form a complete circuit. If you are using a horn, the horn will work and make a sound after turning on the switch, but as long as the lines on the circuit board are broken, the horn will not work properly because they are all interdependent. Therefore, although the circuit of the circuit board is designed to be wound like irregular, there is great wisdom in it.

above is the Shenzhen circuit board factory, multilayer circuit board factory, circuit board factory for everyone to explain the content, want to know more thick copper circuit board content, you can pay attention to us.

thick copper circuit board, shenzhen circuit board factory, multilayer circuit board factory, circuit board factory

Previous Page

Next Page

Previous Page

Next Page

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.