Industry Development of Ceramic Circuit Board

ceramic circuit board industry is no longer an emerging industry, but it is still a thriving "teenager" for China ". Now the domestic ceramic circuit board industry has entered a period of rapid development. All industries have the idea of dividing the cake, and at the same time, they have also integrated the ideas of other fields, directly bringing changes to the entire industry. The biggest change is the channel.

As we all know, when an industry starts to appear more and more competitors, we must consider seizing more markets through more channels. but not ceramic board . The previous ceramic circuit board industry was a purely online industry. All transactions basically relied on offline circle communication, which could ensure that everyone made a lot of money. However, the ceramic circuit board industry used to do is a "land trade" business, fixed in their own circle can not contact the outside world, the outside world can not contact them, want to become bigger is almost impossible. It was not until the capital noticed this cake and began to enable the network mode that the old PCB manufacturers woke up.

Advantages of Ceramic Circuit Board

1, Ceramic Circuit Board has a large loading weight, 100A current continuously passes through a 1mm0.3mm thick copper body, and the temperature rises by about 17 ℃. The 100A current continuously passes through the 2mm0.3mm thick copper body, and the temperature rise is only about 5 ℃.

2. The ceramic circuit board has better heat dissipation performance, low thermal expansion coefficient, stable shape, and warping is not easy to deform.

3, good insulation, high pressure, to ensure personal safety and equipment.

4, strong bonding force, using bonding technology, copper foil will not fall off.

Disadvantages of Ceramic Circuit Board

1, are fragile, which is the main disadvantage of ceramic circuit board, so can only be used for to make small area circuit board.

The price is high, and there are more and more requirements for electronic products. ceramic circuit board is used for relatively high-end products, and low-end products are not used at all.

Ceramic Circuit Board Uses1,

Used in high-power electronic modules, solar cell panel modules, etc.

2,high-frequency switching power supplies, solid state relay

3,automotive electronics aerospace military electronics products

high power LED lighting products

5,communication antenna, automotive igniter

from the overall performance point of view,ceramic circuit board PCB is far better than the usual FR-4 plate, but from the point of view of the cost is also very high! Therefore, it is wise to choose ceramic circuit boards as needed.

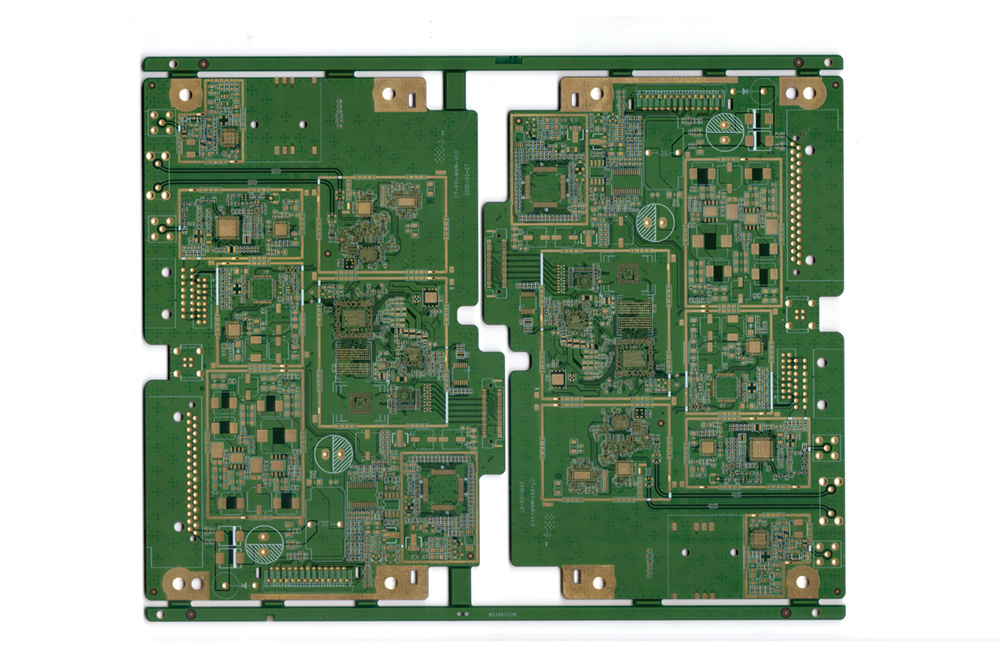

ceramic circuit board

Next Page

Next Page

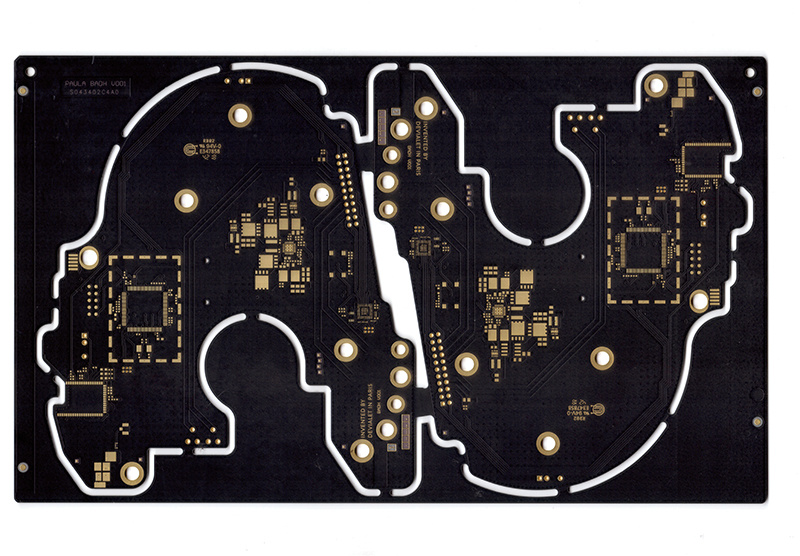

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.