What are the strengths of qualified HDI circuit board manufacturers?

With the development of the times, the equipment used in all walks of life has quite a lot of functions, and the advantages in operation are much more than before. It is precisely for these reasons that it has been favored by everyone, and so is the HDI circuit board. In recent years, there have been many HDI circuit board manufacturers on the market, so you know what strength the qualified manufacturers have ? Let's take a look.

Although it is said that there are many HDI circuit board manufacturers on the market now, some of them are unqualified. We still do not establish such enterprises to choose, because there may be many troubles in the process, and a good HDI circuit board manufacturer has good qualifications and strong strength, the high-quality HDI circuit board manufacturer keeps improving its work quality and has its own professional research team. After comparison, it is found that the annual output of the HDI circuit board manufacturer exceeds 90 square meters. The enterprise passes ISO9001 , and the products all pass UL , QS9000 and ROHS certification. In this way, we don't have to worry about the quality of their products. Since you want to cooperate, what you need to know is that you have been providing superior and fast services for high-tech enterprises and scientific research institutions at home and abroad. The HDI circuit board here is mainly used in communication equipment, computers, detection and control systems, aviation and military equipment and other fields. Producers like this are definitely worthy of our trust and choice. If you have this need, you might as well go here to find out. Since its establishment, the development has been very good.

and qualified HDI circuit board manufacturers have advanced production equipment and perfect control systems in addition to these advantages. Because HDI circuit board manufacturers in order to ensure the power and quality when producing equipment, high-quality manufacturers will definitely invest in advanced equipment, HDI circuit board enterprises have also been selected as the annual suppliers of many well-known enterprises at home and abroad. From their high standards and strict requirements, our process level has been greatly improved in continuous improvement, under such circumstances, it is naturally developing steadily. In addition, the company's market is expanding and expanding. According to our understanding, we also found that we have successfully developed a variety of advanced production technologies such as mechanical micro-holes, high aperture ratio, high-layer backplane, high-precision impedance, HDI , etc. A good HDI circuit board manufacturer also has good value-added services. High-quality manufacturers must not only make good products, but also provide users with added value of various products, and provide customers with suggestions on various product sales plans. Customers also choose to cooperate with them because they see these advantages.

Therefore, the strength and advantages of a qualified HDI circuit board are reflected in all aspects. After understanding these, at least they know where to start when looking for them. Well, that's all for today's knowledge point, hoping to bring help to relevant people.

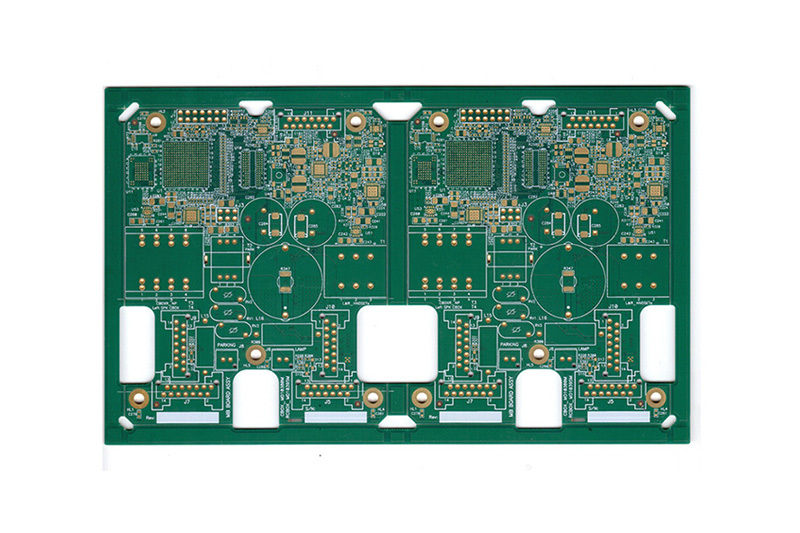

HDI Board

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.