Market Development Prospect of Ceramic Circuit Board

In the era when data is king, PCB industry must keep pace with , ceramic circuit board and must be continuously updated and upgraded with to keep pace with the industrial revolution. With the expansion of LED downstream applications and the increase in market penetration, emerging markets such as high value-added lighting, small-pitch displays, and automotive LEDs will bring incremental space to the industry. Driven by factors such as the expansion of production in midstream packaging plants and the expansion of demand for downstream applications, it is speculated that LED prices are expected to rise or heat up in the future.

LED is a semiconductor device that can convert electrical energy into light energy. It has the advantages of energy saving, environmental protection, safety, long life, and low power consumption. From the industrial chain, LED mainly includes upstream chip manufacturing, midstream packaging and downstream applications. The application of downstream LED is mainly divided into lighting, display, backlight, decoration, automotive lighting and other fields. The application of LED ceramic circuit board is an important link with high added value in the whole industry chain.

Although ceramic circuit board is no longer a new product, its domestic application has just begun. However, compared with other PCBs, ceramic circuit board is a substitute for the old generation of substrates, which can completely replace metal substrates and transparent substrates. Due to its high thermal conductivity, high insulation, better thermal expansion matching coefficient and other characteristics, it is popular in the high-power illumination bright field and . and ceramic circuit board industry has been developed for many years and has matured. At present, the overall market structure is also very clear. Small and medium-sized manufacturers continue to flow in, which is enough to illustrate the prospect of and its market.

In order to improve the luminous efficiency and life ofLED, solving the heat dissipation problem of LED products is one of the most important issues at this stage . provides high heat dissipation, precision size of ceramic circuit board with its heat dissipation also become the trend of future development on LED heat dissipation substrate at the present stage .

ceramic circuit boardthrough aluminum nitride substrate and aluminum oxide substrate to improve the luminous efficiency of LED has become the mainstream of development. Under this development trend, the heat dissipation substrate itself has extremely strict requirements for line positioning accuracy, and requires high heat dissipation, small size, and strong metal line bonding force. Therefore, it has become an important path to use laser technology to promote the high output of LED.

ceramic circuit board in LED downstream applications The largest market is in the lighting field, followed by backlight applications and displays. Among them, the scale of display applications is steadily increasing , , especially with the maturity of small spacing LED display technology, the application of ceramic circuit board has gradually expanded from outdoor large-scale display to indoor application field, further increasing the share of LED display in the entire downstream application industry chain .

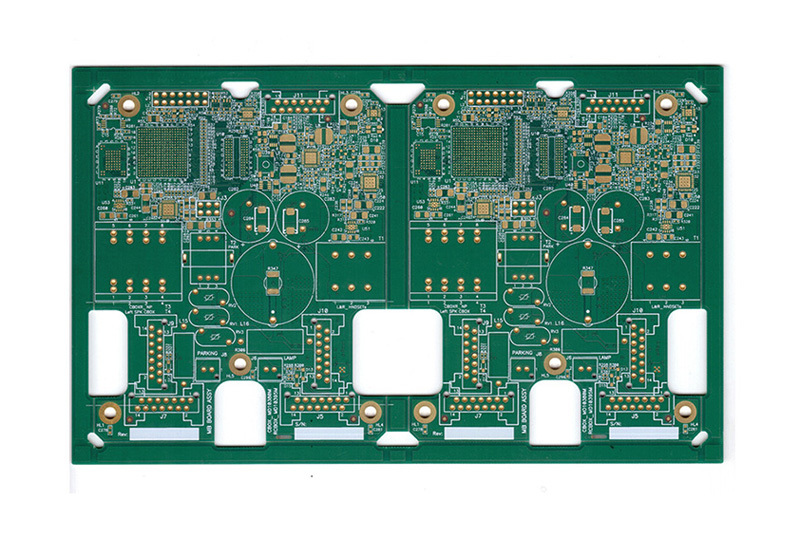

ceramic circuit board

Previous Page

Previous Page

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

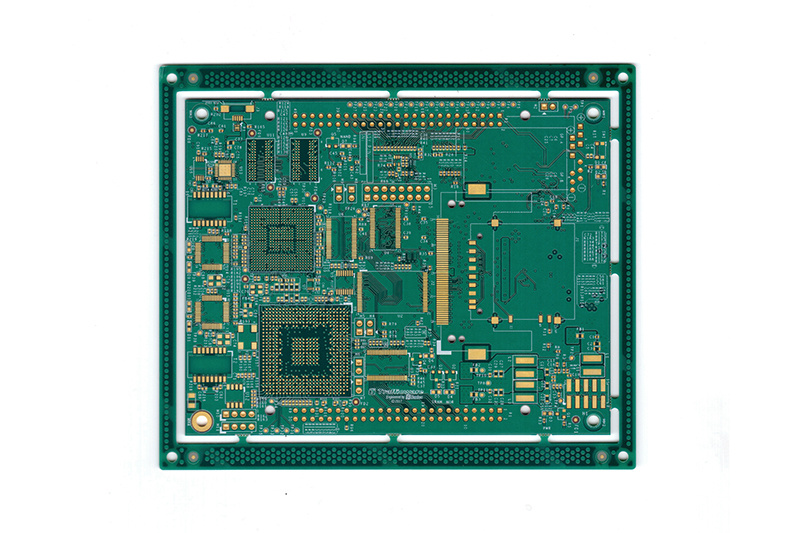

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.