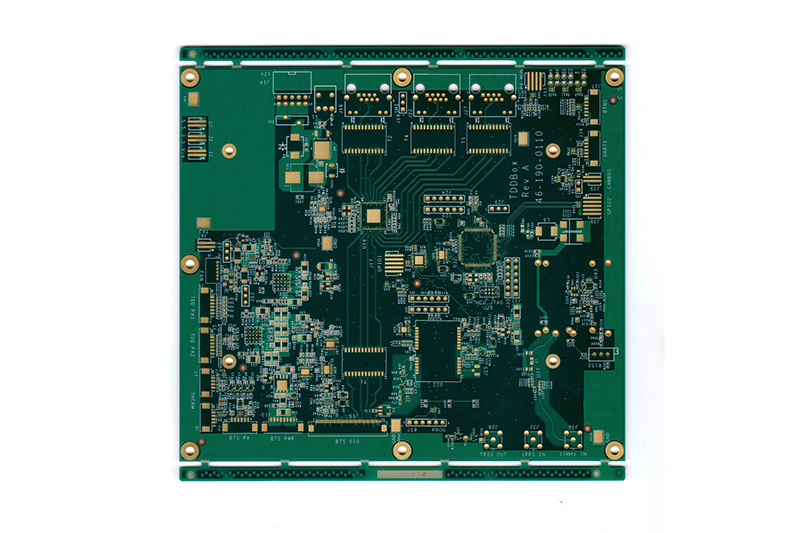

Multi-layer circuit board factory: multi-layer circuit board lamination process problem processing method

multi-layer circuit board laminated total thickness and number of layers and other parameters are limited by the characteristics of the board. Special plates generally have limited varieties of plates with different thicknesses, so designers should consider the limitations of characteristic parameters and processing technology of multilayer circuit boards in the design process of multilayer circuit boards.

As the name implies, laminating multi-layer circuit board is a process of forming a whole by bonding the circuit sheets of each layer. The whole process, including kiss pressure, full pressure, cold pressure. In the kissing stage, the resin infiltrates the bonding surface, fills the gaps in the line, enters the full pressure, and bonds all gaps. Cold pressing is to cool the circuit board quickly and keep the size stable. When making laminates, pay attention to the three major issues of temperature, pressure and time. The main attention is paid to the melting and hardening temperature of the resin, the hot plate setting temperature, the actual temperature of the material and temperature changes, etc. Under pressure, the basic principle is to fill the interlayer cavity with resin and discharge interlayer gas and volatile substances. Time parameters mainly include pressure time control, heating time control, gel time, etc.

When the lamination process problem of multilayer circuit board occurs, the first thing to consider is to integrate this problem into the process specifications of multilayer circuit board , and gradually enrich our Technical specifications, when a certain amount is reached, the quality will change. multi-layer circuit board lamination process quality problems, mostly in the supplier's raw materials or different lamination load quality problems. However, only a few customers can have the corresponding data records, so if most customers can predict the quality control stability and continuity of lamination of multilayer circuit board in advance, many losses can be avoided.

At present, the more effective method to solve the problem is to check the unqualified copper layer on the surface, it is recommended to use hydrochloric acid, and then use the method of machine brush to remove the foreign matter on the surface. Personnel in all processes must wear gloves and must be treated to remove oil stains before and after lamination.

multilayer circuit board, multilayer circuit board factory, multilayer circuit board, PCB circuit board factory, high frequency circuit board

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.