What is the function of each layer of the circuit board? Circuit board factory for you to answer!

circuit board? Circuit board factory for you to answer!

Industrial policy support. The circuit board factory warmly reminds that my country's national economic and social development "Eleventh Five-Year Plan" outline proposes to upgrade the electronic information manufacturing industry, and vigorously develop integrated circuits, software and new components according to the overall trend of digitalization, networking, and intelligence. Core industry. According to the "Information Industry Technology Development" Eleventh Five-Year Plan "and the 2020 Medium and Long-term Planning Outline", printed circuit boards (especially multi-layer, flexible, soft and rigid, green printed circuit board technology) are the next 5-15 years One of the 15 key areas of China's electronic information industry.

The downstream industry continues to grow rapidly. The circuit board factory is a warm reminder that the rapid development of China's information and electronics industry has provided a good market environment for the rapid development of the printed circuit board industry. The continuous growth of electronic products such as communication equipment, computers, and household appliances has provided a strong driving force for the rapid growth of the printed circuit board industry. In addition, the issuance of 3G licenses will trigger large-scale telecommunications investment and drive a large demand for servers, storage and network equipment. According to forecasts, the growth rate of fixed asset investment in telecommunications in mainland China will reach 10.53 per cent in 2006 and 14.29 per cent in 2007.

Labor cost advantage, manufacturing shift to China. The circuit board factory warmly reminds that due to the preferential measures of Asian countries in terms of labor resources, markets, investment, and tax policies, it has attracted the transfer of manufacturing industries from the United States and Europe to Asia, especially China. China has unique conditions. A large number of electronic products and equipment manufacturers have set up factories in mainland China, which has promoted the development of related industries. As the basic electronic components, the market demand is strong and the industry prospect is broad.

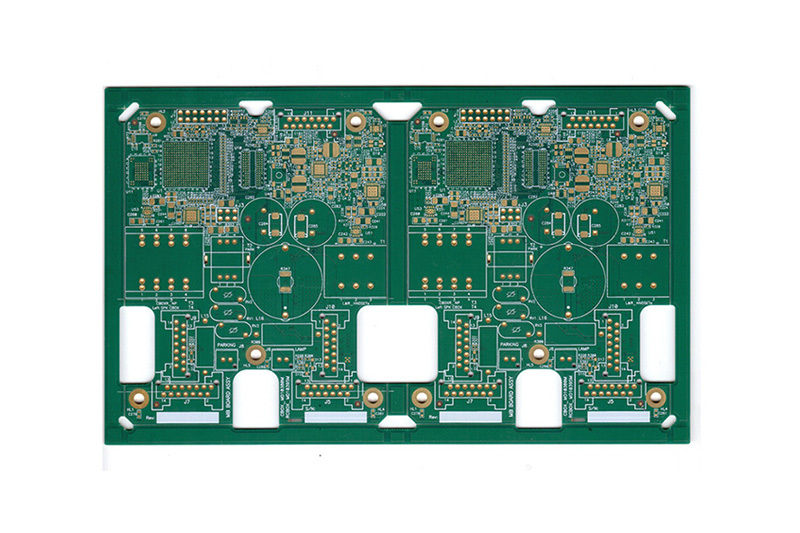

circuit board includes various types of working layers, such as signal layer, protective layer, wire mesh layer, inner layer, etc. What is the function of each layer of the circuit board? Circuit board factory for you to answer!

(1) Signal layer: mainly used to place components or wiring. The Protedxp is usually composed of 30 intermediate layers, that is, intermediate layer 1 to intermediate layer 30, the intermediate layer is used to arrange signal lines, and the top layer and the bottom layer are used to place components or copper.

(2) Protective layer: It is mainly used to ensure that the circuit board does not need to be plated with tin, so as to ensure the reliability of the circuit board operation. The top paste and the bottom paste are a top solder resist layer and a bottom solder resist layer, respectively; the top solder and the bottom solder are a solder paste protective layer and a bottom solder paste protective layer, respectively.

CD screen printing layer: mainly used to print the serial number, production number and company name of components on the circuit board.

(4) Internal layer: Mainly used as a signal wiring layer. Protel DXP contains 16 inner layers.

(5) Other layers: mainly includes 4 types of layers. Drilling orientation layer: mainly used for the location of drilling holes on printed circuit boards. Prohibited wiring layer: mainly used to draw the electrical border of the circuit board. Drill hole drawing layer: mainly used to set the drill hole shape. Multi-layer: mainly used to set multi-layer.

circuit board factory

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.