What does the circuit board factory tell you about the classification of the circuit board?

circuit board factory warm tips, circuit board is circuit board, circuit board name: ceramic circuit board, alumina ceramic circuit board, aluminum nitride ceramic circuit board, circuit board, PCB board, aluminum substrate, high frequency board, thick copper plate, impedance board, PCB, ultra-thin circuit board, ultra-thin circuit board, printing (copper etching technology) circuit board, etc. The miniaturization and visualization of circuit boards play an important role in the mass production of fixed circuits and the optimization of electrical layout. Circuit boards can be called printed circuit boards or printed circuit boards. It is made of polyimide or polyester film. The highly reliable and excellent flexible printed circuit board has the characteristics of high wiring density, light weight, thin thickness and good flexibility. The circuit board factory warmly reminds that the hard and soft board is a kind of circuit board with FPC characteristics and PCB characteristics, which is composed of flexible circuit board and rigid circuit board through pressing and other processes according to relevant process requirements. What are the classifications of

circuit boards? Circuit board factory answers for you!

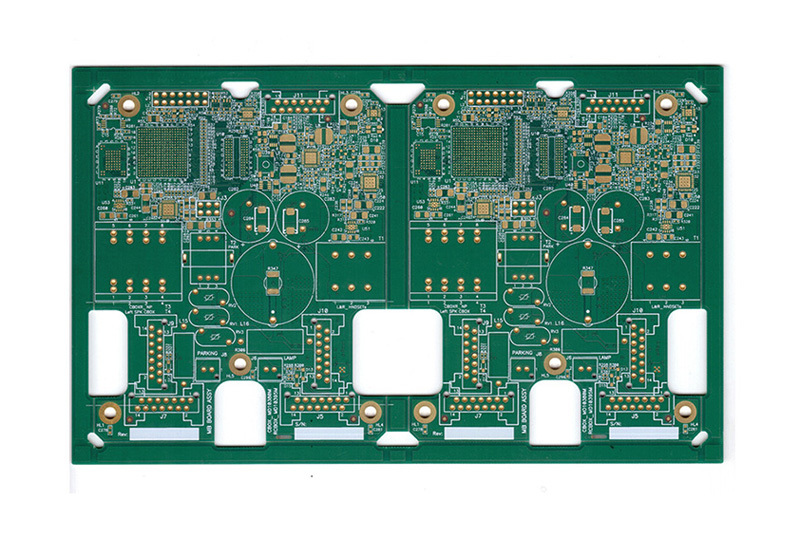

circuit boards are divided into three major categories: single-panel, double-panel, and multi-layer circuit boards according to the number of layers.

is single panel first. On the basic PCB, the parts are concentrated on one side and the wires are concentrated on the other side. Because the wires only appear on one side, this PCB is called a single-sided circuit board. Single panels are usually simple to manufacture and low in cost, but the disadvantage is that they cannot be applied to overly complex products.

The double-sided board is an extension of the single-sided board, so when the single-layer wiring cannot meet the needs of electronic products, the double-sided board will be used, both sides are covered with copper and have wiring, and the wiring between the two layers can be connected through vias., To form the required network connection.

Multi-layer board refers to a printed board with three or more conductive pattern layers, an insulating material is laminated between these conductive pattern layers, and the conductive patterns are connected to each other as required. Multi-layer circuit board is the product of electronic information technology to high speed, multi-function, large capacity, small volume, thin weight.

According to the characteristics, the circuit board can be divided into soft board (FPC), hard board (PCB) and soft and hard board (FPCB).

In use, the circuit board should be maintained regularly to ensure that it is in good working condition and reduce the failure rate of the circuit board. In the use of circuit board maintenance is divided into the following several kinds of situation, circuit board factory for you to answer!

1. Semi-maintenance:(1) Clean the dust on the circuit board every quarter, and use the special cleaning fluid for the circuit board. After cleaning the dust on the circuit board, blow dry the circuit board with a hair dryer. ⑵ Observe whether the electronic components in the circuit have traces of high temperature and whether the electrolytic capacitor bulges and leaks. If so, it should be replaced.

2. Annual maintenance:(1) Clean the dust on the circuit board. ⑵ Sampling inspection of the electrolytic capacitor capacity in the circuit board. If it is found that the capacity of the electrolytic capacitor is less than 20% of the nominal capacity, it should be replaced. Generally, the life of electrolytic capacitors will be replaced in about ten years to ensure the working performance of the circuit board. (3) For high-power devices coated with heat-dissipating silicone grease, check whether the heat-dissipating silicone grease is dry. For dry, remove the dry heat dissipation silicone grease and apply new heat dissipation silicone grease to prevent the high-power devices in the circuit board from burning out due to poor heat dissipation.

circuit board factory

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.