Circuit board factory talk about the corrosion process of PCB circuit board

circuit board factory talk about the corrosion process of PCB circuit board

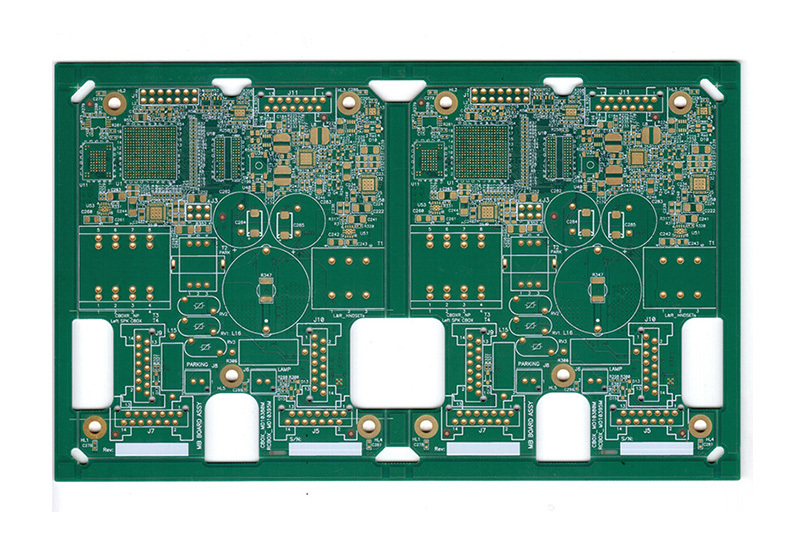

circuit board factory small editor introduced PCB is one of the very common electronic components, almost all electronic products will use PCB. PCB circuit boards are widely used in electronics, computers, electrical appliances, mechanical equipment and other industries. It is the support of components and is mainly used to connect components to provide power. Among them, four-layer and six-layer circuit boards are very common and widely used. Different levels of PCB layers can be selected according to industry applications.

circuit board factory PCB circuit board: also known as printed circuit board and printed circuit board, abbreviated as printed board, abbreviated as PCB(printedcircuitboard board or PWB (Printed Edwin Board)), made of insulating board, cut into a certain size, attached to at least one conductive pattern and hole (such as component hole, fastening hole, metallized hole, etc.).) Distributed in the above, used to replace the chassis of electronic components in the previous equipment, to achieve the interconnection between electronic components. This board is called a "printed circuit board" because it is made of electronic printing. It is inaccurate to refer to a "printed circuit board" as a "printed circuit" because there are no "printed components" on the printed circuit board, only wiring.

PCB circuit board factory PCB circuit board is an important electronic component, is the support of electronic components. The automatic welding machine provides technical support for the welding of PCB circuit boards, so that the development of electronic components continues to progress. However, the corrosion of PBC circuit boards has been plagued by automatic solder merchants.

PCB circuit board factory etching method:

uses disposable etching solution, which can generally corrode multiple circuit boards at one time. The etching solution is usually prepared by adding water to the ferric chloride. Ferric chloride for the earth color solid, easy to absorb moisture in the air, should be sealed preservation.

PCB circuit board corrosion step in circuit board factory: after

is prepared with corrosion solution, corrosion should start from the edge of PCB. When the copper foil not covered with carbon powder is corroded, the circuit board should be taken out in time to prevent the useful circuit from being corroded after the carbon powder falls off.

After the corroded circuit board is taken out, it needs to be cleaned with clean water, and the toner should also be polished with fine sandpaper. Then it is dried to expose the shiny copper foil, and the circuit board is completed.

In order to better preserve the circuit board, the polished circuit board is usually coated with rosin solution, which not only helps soldering, but also prevents oxidation. What is the process of PCB corrosion in

circuit board factory:

corrosion solution is usually prepared by adding water to ferric trichloride. ferric trichloride is an earthy solid and easily absorbs moisture in the air, so it should be sealed and preserved. When preparing ferric chloride solution, 40% ferric chloride and 60% water are generally used. Of course, having more ferric chloride, or warm water (not the hot water that prevents the paint from peeling off) can make the reaction faster. Pay attention to the corrosiveness of ferric chloride, try not to touch skin and clothes, and use cheap plastic cans as reaction containers to place circuit boards. The printed circuit board is etched from the edge. When the unpainted copper foil is corroded, the circuit board should be taken out in time to prevent the useful circuit from being corroded after the paint falls off. At this time, rinse with clean water and scrape off the paint with bamboo chips (at this time, the paint comes out of the liquid and is easier to remove). If it is not easy to scratch, rinse with hot water. Then, wipe dry, sand with sandpaper, and then expose the shiny copper foil, and the printed circuit board is ready. In order to preserve the results, the polished PCB is usually coated with a rosin solution, which not only helps soldering, but also prevents oxidation.

circuit board factory

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.