Circuit board manufacturers talk about the difference between pcb double-layer board and four-layer board

circuit board manufacturer tells us the difference between pcb double-layer board and four-layer board

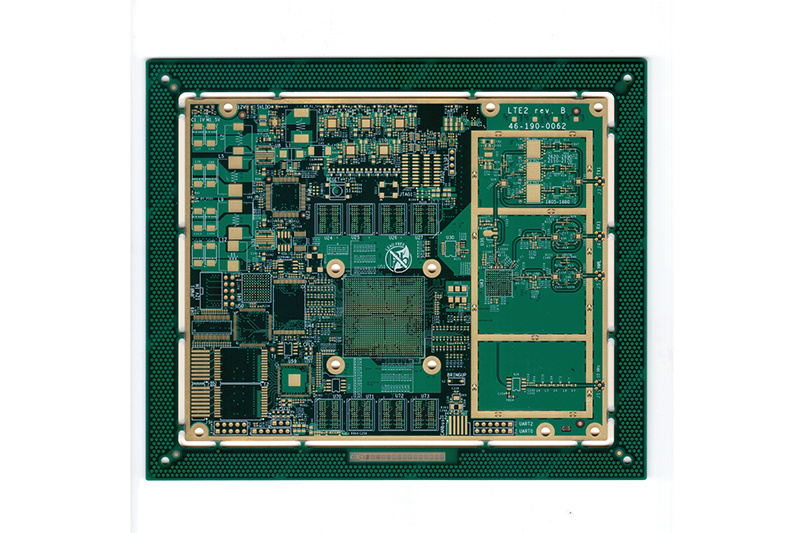

circuit board manufacturer's customized double-sided four-layer circuit board is a common one, of which double-layer board is widely used, followed by four-layer board, while pcb double-layer board and four-layer board are unrecognizable by naked eyes and need slicing technology to know. So how can circuit board factory experts distinguish the difference between pcb double-layer board and four-layer board by not slicing?

Circuit Board Manufacturer: In fact, this method is very difficult to obtain a four-layer board by observing the cross section of the printed circuit board. Few people have this eyesight, but we can identify the four-layer board by observing the guide hole. If the same guide hole can be found on the front and back of the PCB, or the main board or display card is facing the light source, if the position of the guide hole cannot transmit light, it is a four-a light. The four-layer board is laminated on the basis of the double-layer board. When laminating, PP and copper foil are respectively added to both sides of the double-sided board, and then pressed into a multilayer board by high temperature and high pressure. Simply put, the four-layer board has an inner layer. In terms of technology, some lines will be etched through the inner layer and will be pressed up and down. After cutting the delivered board, the double-sided board can be directly drilled.

circuit board manufacturer: how to draw a four-layer board with PROTEL

requires a long-term drawing of a two-layer board. the basic settings are as follows. several layers need to be set, and 16 layers (software functions)(Protel 99se) can be set on one side. the design/layer stack manager can click add layers, and then go to the design/rules/wiring layer, double-click to change the added unused layer to the corresponding value (the wiring method you need). It is important to practice more and often find some relevant settings, such as how thick the wire is, how to add copper plating, and some simulation knowledge. It is often good to simulate people drawing PCB.

Circuit board manufacturer: Four-layer board concept

Four-layer refers to a printed circuit board PCB made of four layers of glass fiber, which can reduce the cost of PCB, but the efficiency is poor. So how to distinguish between four-layer board, double-sided board, single-sided board, six-layer board, etc.? The following is the method to distinguish the number of PCB layers:

circuit board manufacturer: four-layer circuit board storage time:

PCB four-layer circuit board storage time and surface treatment technology has a close relationship. Gold melting and gold plating can be stored for a long time and can be stored for two to three years at room temperature, followed by tin spraying and oxidation resistance, that is, oxidation resistance. After getting the board, it will go online immediately. The storage time is short, about 3 months. The board that has been stored for a long time must be baked before it is put on line, otherwise it is easy to explode during reflow soldering.

If it is a four-layer board with anti-oxidation technology, it will be used up within half a year after vacuum unpacking, within 24 hours after vacuum unpacking, within one year after unpacking under temperature and humidity control, and within one week after unpacking. The temperature and humidity should also be controlled. The gold plate is equivalent to the tin plate, but the control process is stricter than the tin plate.

circuit board factory

The circuit board factory talks about the application advantage analysis of FPC in wearable devices.

2023-07-28

The FPC mentioned by the editor of the circuit board factory has excellent performance and plays an indispensable role in electronic products, meeting the development needs of smart phones and smart wearable devices. With the trend of miniaturization and thinning of electronic products, the consumption of FPC flexible circuit boards is increasing and booming.

Multi-layer circuit board factory-multi-layer circuit board compatible design points description.

2023-07-28

Most electronic products are inseparable from the component is multilayer circuit board, and the production quality of multilayer circuit board factory directly determines the use of electronic equipment and the use of quality, there are many points in the circuit board processing related to the compatibility of multilayer circuit board, and then affect the quality of the circuit board. What are the main points of the compatibility design of multilayer circuit boards under the popular science?_multilayer circuit board_multilayer circuit board factory_blind buried hole circuit board_HDI board proofing

2023-07-28

In the graphic electroplating process method of multi-layer circuit board factory, because the circuit pattern is easy to produce side etching in the etching process, the tin-lead alloy plating part is in the air and produces a suspension layer, which is easy to fall off, resulting in a short circuit caused by bridging between wires. Multilayer circuit board factory uses infrared hot melt process method, can make the exposed copper surface get very good protection. However, when it is used for infrared thermal melting of multi-layer circuit boards, the phenomenon of delamination and foaming between layers of multi-layer circuit boards is very serious due to high temperature, resulting in a very low yield of multi-layer circuit boards. _Blind buried hole circuit board_multilayer circuit board

2023-07-28

Before designing multilayer circuit boards, the multilayer circuit board structure must be determined according to the circuit scale, circuit board size and electromagnetic compatibility (EMC) requirements. That is to decide whether to use a 4-layer, 6-layer or higher multilayer circuit board. Once the number of layers is determined, the multilayer circuit board factory has decided to determine the placement of the electrical layers in the multilayer circuit board and how to distribute different signals on these layers. This is the choice of multilayer circuit board factory laminated structure.